Each producton process starts from sending a master to us by FTP.

All files have to correspond with our specificaton.

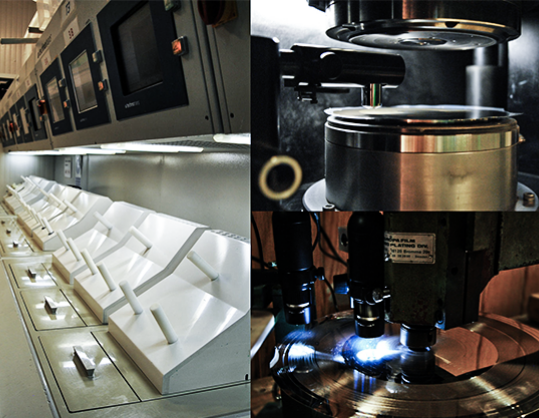

For digital producton we burn disc or load direct master via Eclipse sofware to the DMS Evoluton. At this stage we can find out if the master was correctly prepared and doesn’t contain any errors. First stage of burning (cuttng) is to create 0’s and 1’s. It is done by Laser Beam Recorder (LBR), data are placed in a piece of photosensitve film that has a glass discs as the substrate. This glass disc with the informaton etched onto the film is then coated with thin nickel layer in the inital metallizaton for the next stage. This process takes about one hour.

Afer all the above master is ready for galvanic process.

For analogue production the sound engineer planns tracks order in Pro Tools according to the provided tracklist. He also looks for crucial parts of the master that might create issues and makes test-cuts on Neumann supported by Maselec MTC-1X. If simulations are satisfactory then fresh lacquer is placed on Neumann’s plate and the process begins. Final steps for this process are groove inspection with microscope and adding handmade engraving on the lacquer. This proces takes between one to two hours. After the above lacquer is ready for galvanic process.

For digital production galvanic process is quite an easy one. Glass from DMS is loaded directly to the Technotrans galvanic chamber to increase nickel layer in electro forming process. After reaching about 300µm thickness the process is finished. After a bath in galvanic chamber stampers are washed out and dried.

To complete the process we need to finish stampers. It is a three step process. The first step is to polish back the produced stampers.

The second step is to trim outer edges. And the last step is to do

requested inner hole. After all the above stampers is ready for final measurements. This proces takes about 3 hours.

For analogue production the process is much longer. The lacquer received from the cutting department has to be mechanically and chemically treated. The mechanical treatment is done to make galvanic the process possible. The chemical treatment contains degreasing and silvering. After preparations lacquer can finally go for galvanic process. For direct production (1-process) there are two galvanic processes hi-speed and low-speed. There is also a possibility to produce stampers in family process despite the chosen options there could be Father/Mother (2-process) or Father/Mother/Son (3-process). To check which option is the best for you please check your specification file. After finishing the galvanic process the stamper is washed out and dried. This process also has to be finished. All plates are polished at the back. Remaining processes depends on customer request. It could be trimmed inner/out and coined for Phoenix Alpha machine. To check diameters of finished/unfinished stamper please see specification file. The whole production takes from six to twelve hours.

All digital stampers are checked in DATARIUS or AudioDEV testers. Tests are done in partial mode, which means 8 points are randomly measured. If needed we could perform the whole stamper test

– it could prolong the production process. If tests results are correct we are ready to dispatch.

Measurement for each stamper takes around half an hour.

Produced stampers are dispatched usually after 24h from receiving

full set for order -> master and order form.

For analogue stampers there is no measurement option. There is only possible to check if this stamper is produced in family process we could listen to Mother set (optional). Stampers are ready to be dispatched usually after 10days from receiving whole data -> master, tracklist and order form.

stampers for CDs/DVDs

digital@opticaldiscmastering.eu

cutting / galvanic & finishing

Optical Disc Mastering Sp. z o.o.

45/53 Heliotropów st.

04-796 Warsaw, Poland

VAT PL5242756419